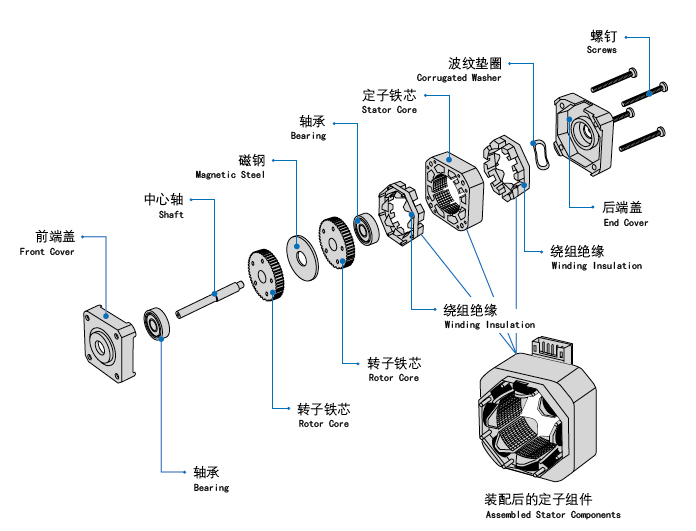

The basic structure of a stepper motor is mainly composed of front and rear end covers, bearings, center shaft, rotor core, stator core, stator assembly, corrugated washers, screws, etc. As a motor that can rotate according to a specific number of steps, the components and functions of the stepper motor are crucial to realize its position control function.

1. Stator: The stator core is the motor's stationary part and provides the magnetic field's basic structure. The stator winding is tightly wound on the core, and when current passes through it, a magnetic field is generated. This magnetic field interacts with the magnetic field of the rotating part (rotor), thereby driving the rotation of the rotor. The design of the stator has an important impact on the performance and accuracy of the stepper motor.

2. Rotor: The rotor is the rotating part of the motor. It rotates under the action of the magnetic field generated by the stator to realize the mechanical movement of the motor (each time an electrical pulse signal is input, the rotor will rotate at a fixed angle). The shaft, as the core component of the rotor, transmits the rotational motion to the external load. The rotor's design and material selection directly affect the motor's output torque and rotation accuracy.

3. Bearing: Support the mechanical rotating body, reduce the friction coefficient during the movement, and ensure rotation accuracy. Bearings are essential for the smooth operation of the motor and can effectively reduce energy loss and mechanical wear.

4. Others: Such as front and rear end covers, center shaft, corrugated washers, screws, etc., these components together constitute the overall structure of the stepper motor to ensure its stable and reliable operation.

The design and construction of stepper motors are to achieve precise angle control. Through external control pulse signals, the stepper motors rotate step by step at a fixed angle, thereby achieving precise position control. This feature makes stepper motors very useful in applications that require high-precision positioning, such as CNC machine tools, printers, plotters, and other equipment.